ARCHITECTURAL WOOD DOORS

We provide solid core, architectural grade flush wood doors, pre-finished wood doors, plastic laminate doors, Fire Rated doors and stile and rail wood doors for a variety of commercial and institutional applications, including office buildings, hotels, hospitals, medical centers, schools, apartment buildings and more.

Just like hollow metal doors, architectural wood doors are durable enough to withstand heavy and frequent use. And, wood doors provide an aesthetically pleasing appearance.

Wood doors of all sizes and types can be pre-machined to accommodate almost any hardware application; everything from lock cutouts, hinge pockets, electric access cardlocks, concealed vertical rods to lite and louver inserts.

PRODUCT DESCRIPTION

Haley Bros. 5-Ply Particle Board Core construction provides the highest quality door used in the industry.

All doors meet or exceed current industry standards

- Current WDMA I.S. 1A

- W.I.C. Section 20

- A.W.I. Section 1300 when specified

ITEM SPECIFICATIONS

- Maximum Size: 4′- 0″ x 8′ – 0″

- Thickness: 1 3/4″ only

- Stiles: 1 3/8″ laminated hardwood bonded to core

- Rails/Lock Blocks: 1 1/4″ minimum wood bonded to core

- Core: Particle board. Meets or exceeds requirements of ANSI A208 and CS236-66. Abrasively planed before veneering

- Adhesives: Type 2. Type 1 available

- Faces: Check with Haley for current availability.

- Vision Panels & Louvers: Total area of openings not to exceed 40% of door area or 50% of door height, must be a minimum of 5″ from door edges

- Prefitting: May be prefit to net sizes as specified

- Machining: May be factory machined for hardware as specifed

STANDARD HOLLOW METAL DOOR DESIGNS

Standard door designs shown below. Custom designs available upon request.

QUALITY FROM THE INSIDE OUT.

- Stiles and Rails Bonded to Core

- Architecturally Selected Core

- Particle Board

- Lumber Core

- Mineral Core

- Special Purpose Core

- Premium Face Veneers or Laminate

- Matching Hardwood Edges

- Certified Premium Quality—Meets or Exceeds AWI Section 1300, NWWDA I.S.1, WIC Section 20

- Protective Packaging

- Lifetime Warranty Available

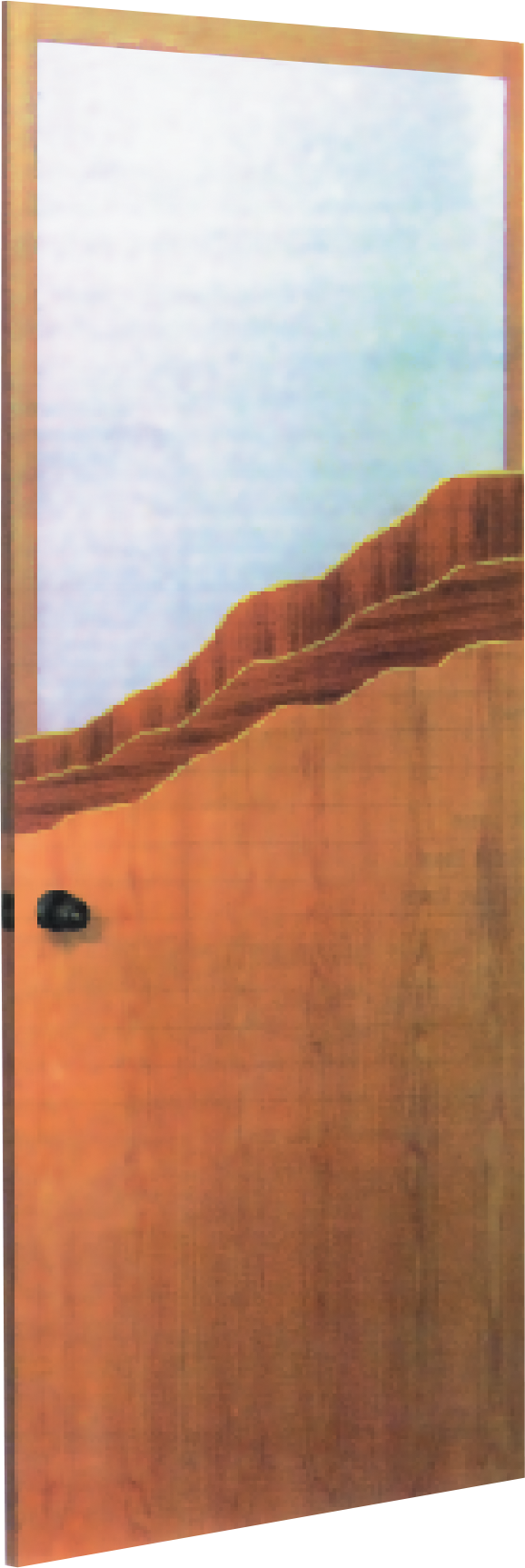

GOOD LOOKING, LONG LASTING FACTORY FINISH.

Nothing looks better or performs better than a Haley factory finish. Factory craftsmen, working in a controlled environment, are able to produce an exceptionally durable finish with a uniformity in color and texture seldom attainable on the job site. Because wood surfaces are sealed at the factory, they are more resistant to unfavorable job-site storage conditions. A factory finish offers cost benefits as well. Installed costs are actually lower than for doors finished at the job site. Factory finish is offered in a wide range of standard colors with custom and proprietary colors also available.

- Because doors arrive ready for installation, delivery can be scheduled after other trades are done for less job-site damage.

- Costs less than a field-applied finish.

- Expert application in a controlled environment produces a finish superior to what is possible in the field.

- Wood surfaces are protected from unfavorable job-site storage conditions.

- Environmentally safe ultraviolet curing process is approved by EPA, OSHA, and AQMD

- Long-term availability of color-matched replacements.

- Performance warranty stays with one single, responsible source.

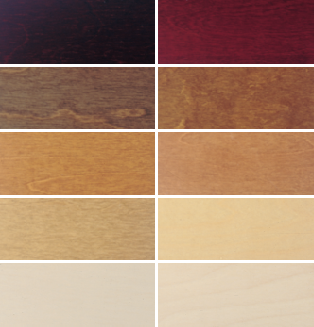

ALDER-CLEAR

ALDER-KNOTTY

ASH

BIRCH

CHERRY

FIR

HICKORY

KNOTTY PINE

MAHOGANY

MAPLE

OAK

PINE

MAHOGANY

MAPLE

OAK

CLEAR AND KNOTTY ALDER

Alder is the leading hardwood of the Pacific Northwest. Alder, a relative of birch, is almost white when freshly cut but quickly changes on exposure to air, becoming light brown with a yellow or reddish tinge. Heartwood is formed only in trees of advanced age and there is no visible boundry between sap and heartwood. The wood is fairly straight-grained with a uniform texture. Alder machines well and is excellent for turning. It can be painted or stained to a good finish. When stained, it blends with walnut, mahogany or cherry. Knotty Alder is a lower grade that will contain knots. Knotty Alder is commonly used for the southwest look.

HARD WHITE MAPLE

Maple has been a favorite of American furniture makers since early colonial days. Hard maple is the standard wood for cutting boards because it imparts no taste to food and holds up well. The sap wood is creamy white with a slight reddish brown tinge The wood has a close fine, uniform texture and is generally straight-grained. Maple can be stained to an outstanding finish and polishes well.

AFRICAN MAHOGANY

An excellent cabinet and veneer species because of its long trunk form, rapid growth, and attractive pinkish-red to deep reddish brown lustrous wood. Interlocked or straight grain, often with a ribbon figure, and a moderately coarse texture. Mahogany has a reddish brown heartwood, often with a purple cast. Mahogany stains and polishes to an excellent finish.

CLEAR AND KNOTTY PINE

One of North America’s most abundant species, Western pines include Ponderosa, Sugar and Idaho White Pine. Ponderosa Pine is perhaps the most beloved of Western pines. Its soft texture and light color distinguish it from Southern pines; its wood is among the most beautiful of all pines. Sap wood is nearly white to pale yellow, heartwood is light to reddish brown. Clear finishes with UV blockers can help retain its freshly-milled color. It has a pleasent pine scent and is slightly resinous. Knotty Pine contains knots that foster the log home look.

POPLAR

Poplar trees grow taller than any other U.S. hardwood species and they are members of the magnolia family. The sapwood is creamy white and may be streaked, with the heartwood varying from pale yellowish brown to olive green. The green color in the heartwood will tend to darken on exposure to light and turn brown. The wood has a medium to fine texture and is straight-grained; and has a comparatively uniform texture. A versatile wood that is easy to machine, plane, turn, glue and bore. It takes and holds paint, enamel and stain exceptionally well.

RED OAK

The oaks have been key in America’s industrial transformation: railroad ties, wheels, plows, looms, barrels and of course, furniture and doors. The sap wood of red oak is white to light brown and the heartwood is a pinkish reddish brown. The wood is similiar in general appearance to white oak, but with a slightly less pronounced figure due to the smaller rays. The wood is mostly straight-grained, with a coarse texture. Red oak machines well and it can be stained to a good finish with a wide range of tones.

WALNUT

Walnut is a prized species for veneer panels, doors, furniture and cabinetry, with a warm, rich, high-quality appearance. The heartwood of walnut is light brown to dark chocolate brown, occasionally with a purplish cast and darker streaks. The wood develops a rich patina that grows more lustrous with age. The wood is generally straight-grained, but sometimes with wavy or curly grain that produces an attractive decorative figure. This species produces a greater variety of figure types than any other. Walnut is easy to work with and it holds paint and stain very well for an exceptional finish.

ASH

Ash belongs to the olive family, although its only fruit is a dart-like winged seed. Ash is a popular species for food containers because the wood has no taste. The sap wood is light-colored to nearly white. The wood is generally straight-grained with a course uniform texture. Ash machines well and can be stained to a very good finish. Ash has very good overall strength properties relative to its weight, and has excellent shock resistance.

EASTERN WHITE BIRCH

From sap to bark, birch trees are used to make everything from beer to tooth picks. Birch has a white sapwood. The wood is generally straight-grained with a fine uniform texture. Generally characterized by a plain and often curly or wavy pattern. The wood works fairly easily, glues well, and takes stain extremely well.

CHERRY

Like all fruit trees, cherry belongs to the rose family. American colonists used the cherry tree for its fruit, medicinal properties and home furnishings. The heartwood of cherry varies from rich red to reddish brown and will darken with age and on exposure to light. The wood has a fine uniform, straight-grain, satiny, smooth texture, and may naturally contain brown pith flecks and small gum pockets. Cherry is easy to machine, nails and glues well and when sanded and stained, it produces an excellent smooth finish.

DOUGLAS FIR

Douglas Fir grows throughout Western forests with the most abundant region being in coastal climates of Oregon, Washington and northern California. Fir’s light rosy color is set off by its remarkably straight and handsome grain pattern. Sap wood is white to pale yellow; heartwood is russet with high contrast between the springwood and summerwood. Douglas Fir doors, manufactured from the products in the Factory and Shop grade classification, are renowned for their beauty and performance.

HICKORY

In Eastern North America, hickory survived the catastrophic changes of the Glacial Epoch, some 50 million years ago. Thus, it is the first strictly American hardwood species. Hickory is the hardest, heaviest and strongest American wood. The sapwood of hickory is white, tinged with inconspicuous fine brown lines while the heartwood is pale to reddish brown. Both are coarse-textured and the grain is fine, usually straight but can be wavy or irregular. The wood can be sanded to a good finish. The grain pattern welcomes a full range of medium-to-dark finishes and bleaching treatments.

PRIMED

We generally prime coat our fir doors when primed is requested. Primed M.D.F. is another option.